- Self-balance Multistage Pump

- Horizontal Multistage Pump

- Vertical Multistage Pump

- Boiler Feed Pump

- Split Case Pump

- Single Stage Pump

- Chemical Process Pump

- Mining Pump

- Oil Pump

- Pneumatic Diaphragm Pump

- Diesel Engine Pump

- Sewage Pump

- Inline Pump

- Submersible Pump

- Condensate Pump

- Mud Pump

- Axial Flow Pump

- Mixed Flow Pump

- Fire Fighting Pump

- Vacuum Pump

- Vertical Long-shaft Pump

The type, structure and function of the condensate pump are explained in detail

Condensate pump is one of the important components of the main condensate system, which can also be called condensate drainage pump, or condensate pump for short. The main condensate system refers to the piping and equipment associated with the condenser to the deaerator. In general, the main condensation system consists of two condensate pumps, condensate refining units, a shaft seal heater, four low-pressure heaters, a condensate refill tank and two condensate refill pumps. In order to ensure the safe and reliable operation of the system during start-up, shutdown, low load and equipment failure, the system is equipped with numerous valves and valve groups. The main condensate flow is as follows: condenser hot well → condensate pump → condensate finishing device → shaft seal heater → No. 8 low pressure heater → No. 7 low pressure heater → No. 6 low pressure heater → No. 5 low pressure heater → Deaerator. The condensate pump pumps the condensate water out of the condenser's hot well under the condition of high vacuum, and delivers the water close to the saturation temperature of the condenser pressure. One frequency conversion operation and one power frequency standby.

First, the model of condensate pump

1. GNL vertical condensate pump

GNL vertical condensate pump is a two-stage single suction centrifugal condensate pump with vertical structure. Suitable for power plants, used to pump condensate in the condenser and 750 ~ 3000kw steam turbine generator units to pump condensate or other liquids with physical and chemical properties similar to water. The liquid temperature does not exceed 80℃. Pump inlet pressure is not higher than 0.6MPa.

2. N series condensate pump

N type condensate pump is a single stage single suction cantilever centrifugal condensate pump, N series NB, NBA, GN, N type, are horizontal, using rolling bearings, grease lubrication, shaft seal for packing seal, can also be used mechanical seal.

Second, the structure of the condensate pump

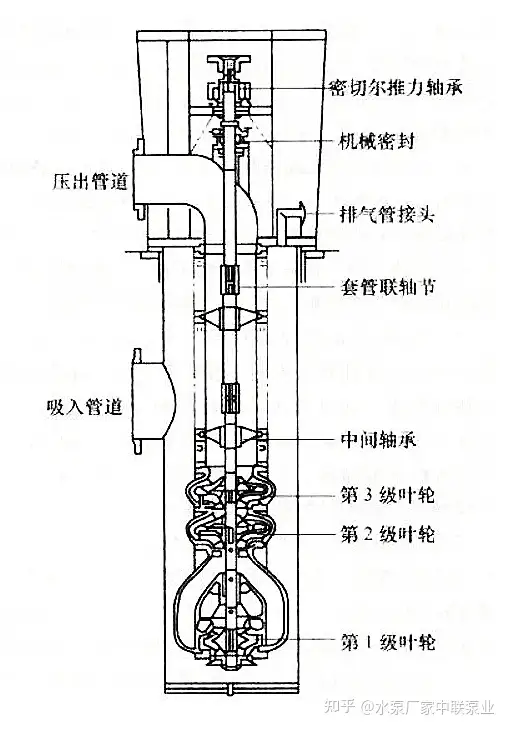

The condensate pump is mainly composed of the suction horn, the first stage impeller, the second and third stages of the pump, the support pipe and the drainage elbow, the mechanical seal, the bearing and the motor. The following figure shows the structure of the three-stage vertical caisson type condensate pump.

Condensate pump structure drawing

1) The condensate pump suction inlet and the first stage impeller of the pump

The first stage of the condensate pump adopts a two-sided suction design to meet the specified requirements of the suction specific speed without excessive increase in the length of the pump. A horn directs water flow into each impeller hole in a steady and optimal flow rate distribution. The water discharged from the edge of the first stage impeller is introduced into the second stage by the double volute. At the joint surface of the double volute, in the lower flare, a bearing lubricated by condensate water provides support for the pump shaft. In order to facilitate maintenance, the operating clearance of the journal and the impeller neck is provided with a replaceable sleeve and liner.

2) The second and third stages of the pump

The second and third stages of the pump are unilateral water inlet, so each stage has a unilateral water inlet impeller operating in a diffused shell. The inlet of the impeller faces down towards the front stage and is fitted with a reverse neck ring and balance chamber to minimise hydraulic loads. Guide vane channels direct water from the edges of each impeller to the suction inlet of the next impeller. Each stage of the pump housing has a set of condensate lubricated bearings to support the pump shaft. The impeller is fixed on the shaft by a key, and is positioned axially by a sleeve that is close to the end and shoulder of the shaft.

3) Support pipe and drainage elbow

The condensate discharged from the last stage of the pump flows out of the pump through a vertical pipe, also called a support pipe, which also supports the weight of the pump. A steel drainage elbow and motor support joint mechanism, not only plays the role of drainage, but also hangs the whole pump body, and supports the motor driving the pump on its top flange.

4) Mechanical seal

A mechanical seal is provided in a packing box where the pump shaft passes through the drain elbow to prevent leakage along the pump shaft. A hole is opened on the sealing pressure plate for connecting the sealed water pipe. The condensate water drawn from the condensate pump outlet pipe is cooled and sealed by the decompression device during operation, and the air is organized when the pump is shut down.

5) Bearing

Thrust bearings and radial bearings mounted on the motor bracket of the condensate pump bear the weight of the rotating parts and the hydraulic load applied. Bearings are equipped with an integrated lubricating oil system. The design load capacity of the bearing is very large, and it can operate under certain overload conditions.

6) Motor

The condensate pump is driven by a vertical cage induction motor.

Third, the role of the condensate pump in the condensate water system

During normal operation, the condensate water replenishment tank replenishment water to the condenser hot well, return water at the high water level of the heated well, and provide chemical supplementary water; Supply start-up water to condensate and closed water systems during unit start-up. The water source of the replenishment tank comes from the dehydrated water from the chemical water treatment room, and its water level is controlled by the regulating valve of the replenishment water inlet pipe.

Condensate water transfer pump is mainly used to inject water into thermal system, boiler and closed water system when starting.

The pump is provided with a bypass through which water is supplied to the condenser by the pressure difference between the water tank and the condenser vacuum during normal operation of the unit. When the vacuum direct water supply cannot be satisfied, open the condensate pump to water the condenser.

The condenser water supply control device is configured with two channels: one for normal water supply and the other for a large amount of water supply when unqualified condensate water is discharged during startup. When the unit is started, water can be supplied to the boiler by the condensate water conveying pump through the condensate water system. The outlet of condensate pump is provided with a minimum flow recirculation pipeline.